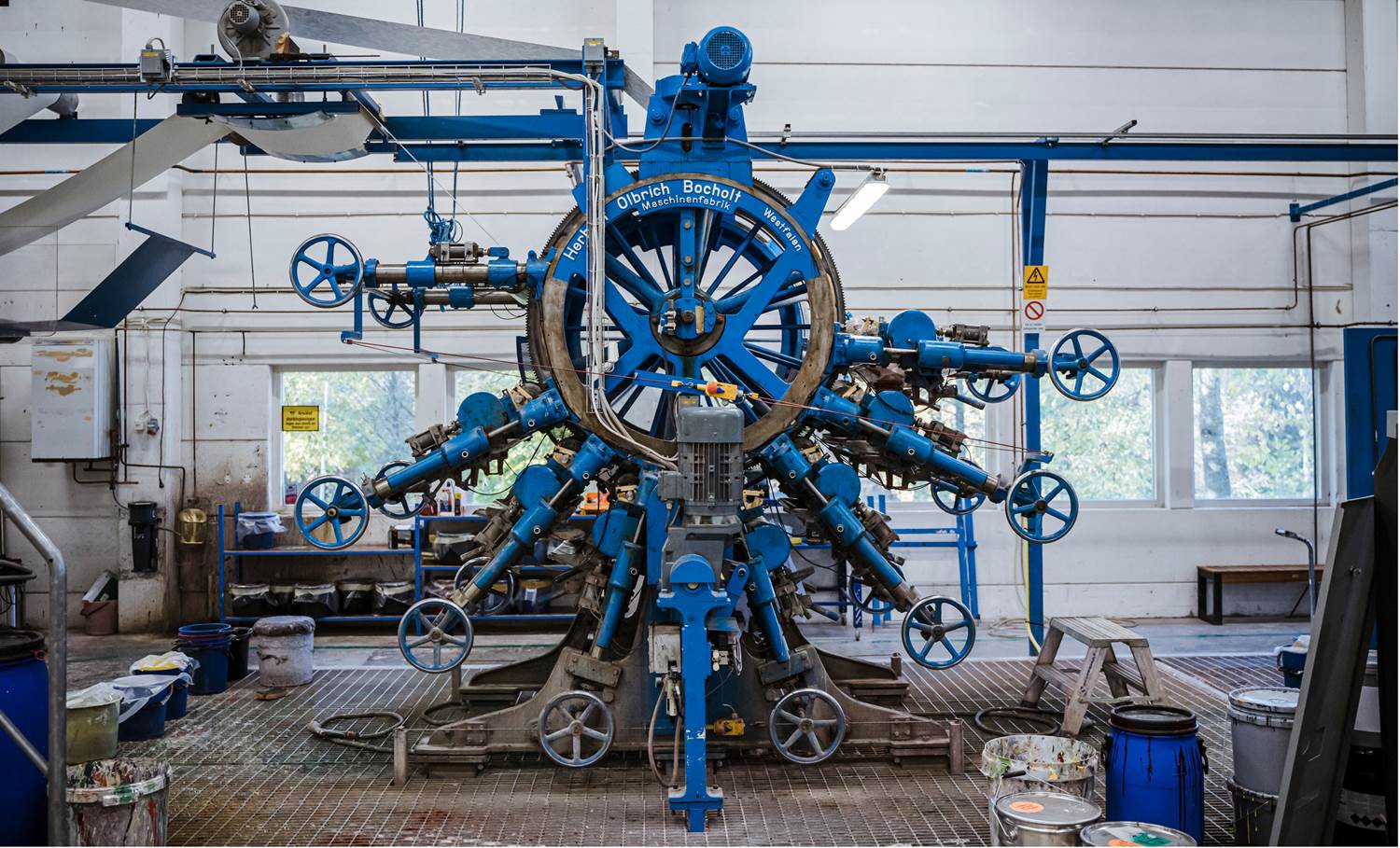

Screen printing

Wallpaper with Estrid Ericsson’s Elefant design are printed using screen printing. The technique is not as old as distemper printing, and is somewhat more automated. In conjunction with screen printing, stencils are used where the colour is pressed out through small holes and creates the design image. In this way, many fine details can be printed since the technique is more exact and creates a fine depth. When screen printing, transparent colours can also be used, which provides a lovely watercolour effect.

The Elefant pattern is printed using a stencil and obtains a fine, matt expression. In the final stage, a layer of transparent colour is added which makes the wallpaper hardy and also dryable.

Ulricehamns Tapetfabrik has a unique screen printing machine. It was extended 10 years ago and two new printing stations were added, which makes it possible to print more advanced patterns with more colours. Printing master Göran Bylin is one of those who works with production. He has been here since the start and, with 30 years’ experience, he knows the machine’s qualities, weaknesses and strengths to a tee.